Dyeing

Our approach to the fabric dyeing process is lined with the sustainable production commitment we implement at our facility.

Our fabric dyeing methods are;

- Reactive dye

- Disperse dye

- Acid dye

The production process covers all the requirements of REACH, Oeko-Tex 100, ZDHC MRSL, GOTS, and Bluesign BSBL certificates. Intermediate controls during the fabric dyeing process are carried out in our advanced laboratory. At the end of the production, we pass it through the final quality control.

Our HT dyeing machines are equipped with low Flotte usage as a requirement of eco-production. All chemicals used in the production process are delivered via liquid chemical autonomous systems without human interaction. This system helps us ensure materials’ exact usage within the bill of materials list. We do not compromise on quality and sustainable production standards thanks to our advanced technology production line. In addition, our dyeing machines can provide different levels of production volumes, such as samples or high-capacity orders.

Our Dyeing Process

The first phase of the dyeing operation is the coloring process. Thanks to our dye laboratory working with an automatic dosing system, a high level of color delicacy and continuity are ensured. All processes regarding coloring, taking into account all fastness demands and certificate standards, are done by the coloring labs and recorded.

Color controls are performed both visually, under the light requested by the customer in the light cabinets in the dark room, and with the spectrophotometer precisely. The details and test values of each production lot were recorded to ensure colour continuity.

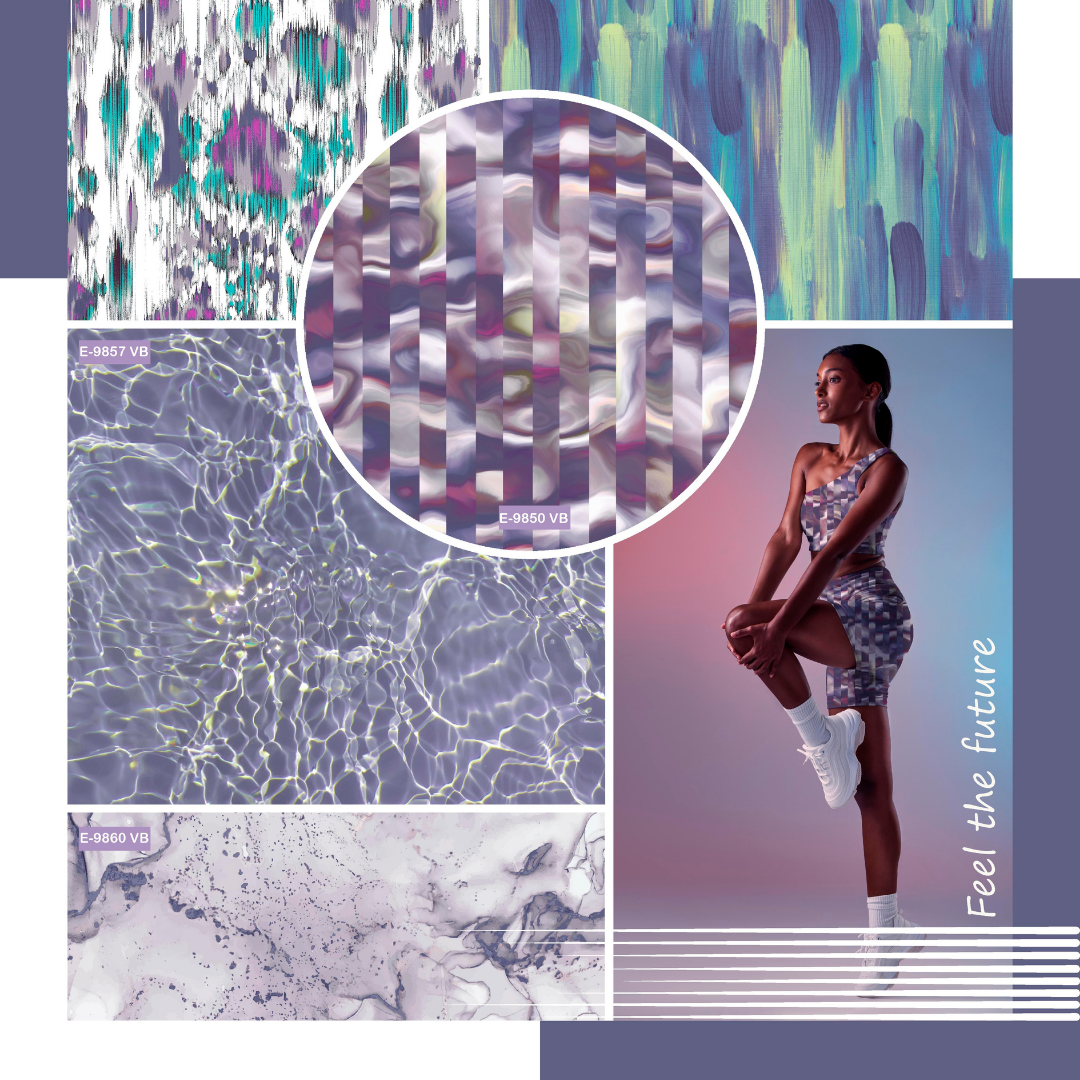

One-Stop Solution for Dyeing and Printing Needs

At Zeynar, we provide fabric dyeing and printing processes in our facility. This helps our customers to collect dyed and printed product needs from a single vendor, reducing the supply process while optimizing the logistic timeline.